Wool

- Books Name

- CBSE Class 7 Science Book

- Publication

- Param Publication

- Course

- CBSE Class 7

- Subject

- Science

(i) Wool :

We wear sweaters in winter to protect ourselves from the cold. Wool is a fibre obtained from animal such as sheep, goat, yak and lamb. Animals from which we get wool bear a thick coat of hair on their bodies.

Wool fibres keep us warm the thick coat of hair traps a lot of air, thereby creating an insulating barrier.

Wool is a fibre obtained from the fleece (hairy growth) of these animals. Wool fibre is made up of protein. It is usually white in colour, although, it can also be brown or grey. Wool is mainly derived from sheep.

Wool comes from sheep, llama, alpaca, guanaco and vicuna.

Remember

• Difference between fleece and hair

Fleece : Thick covering of wool on a sheep, used to make a piece of clothing Hair : The mass of thin thread like structure that grows out of the skin

(a) Wool from Sheep

A sheep’s hairy coat has two types of fibres :

(i) the coarse beard hair and (ii) the soft under-hair, found close to the skin. It is the soft under-hair that is used to make wool. Scientists have developed certain breeds of sheep that only have the soft under-hair.

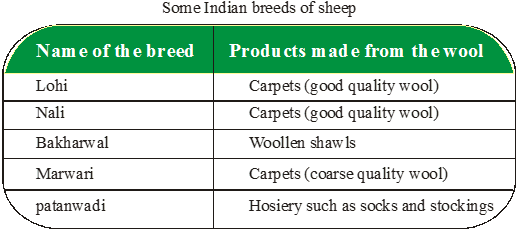

The wool from different varieties of sheep differes in fineness, shine, length, and strength. The finest wool is obtained from the Merino, a breed of sheep originally from Spain. Their wool is very soft and light, and is therefore used in making the finest woollen clothes.

(b) Rearing of Sheep

In India, sheep are reared in the hilly regions of Jammu and Kashmir, Himachal Pradesh, Uttarakhand, Arunachal Pradesh, Sikkim, Punjab, Haryana, Rajasthan, and Gujarat.

Remember

• Breed : A particular type of animal developed for certain desirable characteristics

• Rearing : Keeping animals and caring for them to obtain useful products

(c) Wool Production

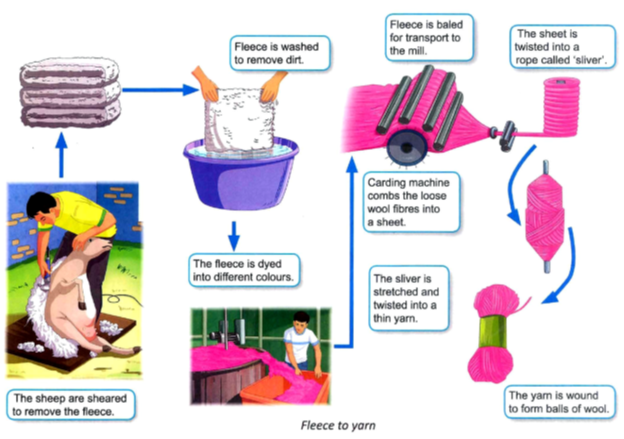

Sheep hair is sheared off from the body, scoured, graded or sorted, dried, dyed, spun and woven to yield wool.

• Shearing : The fleece of the sheep along with a thin layer of skin is removed from its body. This is called shearing.

Sheep are usually shorn annually in the spring/summer months.

Just as a haircut does not hurt us, shearing does not hurt the sheep, it actually helps them by removing the heavy woollen coat that they do not require in summer.

• Scouring :The sheared skin with hair is thoroughly washed in tanks to remove grease, dust and dirt. This is called scouring.

It is done with the help of machines.

• Grading or Sorting : In this process, the wool is sorted on the basis of length, colour, texture, and the ease with which it can be dyed (coloured).

• Dyeing : As the natural colour of fleece is white,brown or black, the sheared wool is dyed in different colours.

• Drying : In this process, containers of wool are put through rollers to squeeze out as much water as possible. Then the wool is weighed and packed into bales. The bales are transported to the mills where they are processed further.

• Making of Yarn :

Figure explains how the fleece is woven into yarn.

(d) Health Hazards in the wool industry :

• While sorting wool, workers (sorters) get infected by bacteria, anthrax, which causes fatal blood disease called sorter’s disease. Such risks faced by workers in any industry are called occupational hazards.

Nowadays, this disease occurs rarely because of the use of vaccines for prevention.

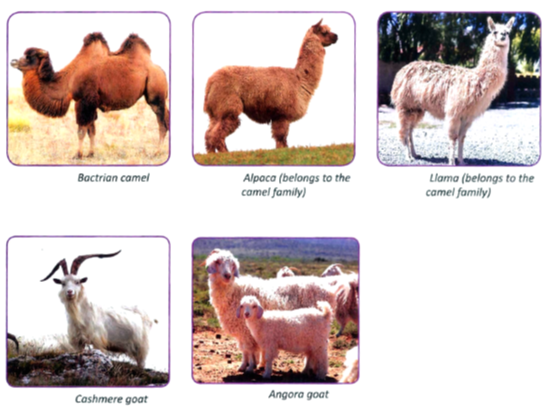

(e) Wool from other Animals

• Angora wools is obtained from angora goats, which are found in hilly areas like Jammu and Kashmir.

• Yak wool is commonly found in areas like Laddakh and Tibet.

• Wool obtained from Kashmir goat is soft and is used to weave fine quality shawls called Pashmina shawls.

• Wool is also obtained from fur (hair) on the body of camels. It is used in making carpets etc.

• Llama and Alpaca, found in South America, also yield wool.

• Wool is used for making coats, suits, shawls, scarves, gloves and carpets. It traps air and so it has insulating properties.

Wool

Wool

Wool is an animal fibre obtained from the fleece or hairs of sheep, goats, yak or camels. Hairs of these animals trap air to keep their body warm in winters. Due to this reason, they are used to making woollen clothes.Woollen fibres to woollen fabrics

Shearing -The fleece of sheep or other wool yielding animals is removed along with a thin layer of skin. This process is just like shaving.

Scouring – After the hairs are removed, they are thoroughly washed and cleaned to remove any dust, dirt, or grease.

Sorting – After scouring, hairs of different textures are sorted.

Cleaning of Burrs – The small, fluffy burrs that appear on hairs are then removed. After this, long woollen fibres are made.

Dying – To give desirable colour to the fibres, they are dyed.

Rolling – Finally, woollen yarns are made by rolling them. After that, these wools are knitted into desirable shapes and sizes to make sweaters, mufflers, socks, etc

Silk

- Books Name

- CBSE Class 7 Science Book

- Publication

- Param Publication

- Course

- CBSE Class 7

- Subject

- Science

(ii) Silk :

Silk is an animal fibre derived from silkworms. Silk is produced by a moth (species) known as silk moth. The scientific name of silk moth is “Bombyx mori”.

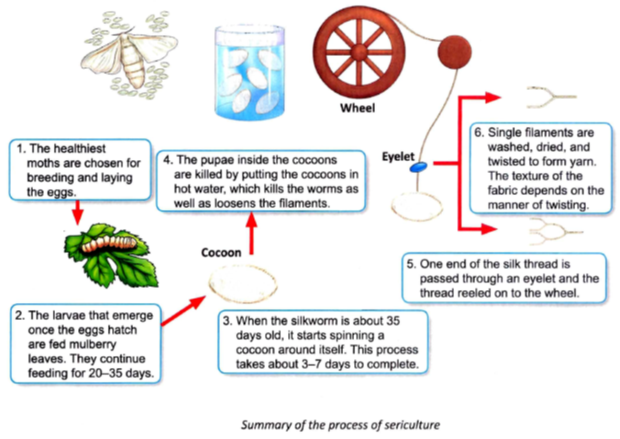

The breeding of these silk moths for production of silk is known as “sericulture”.

(a) Production of Silk :

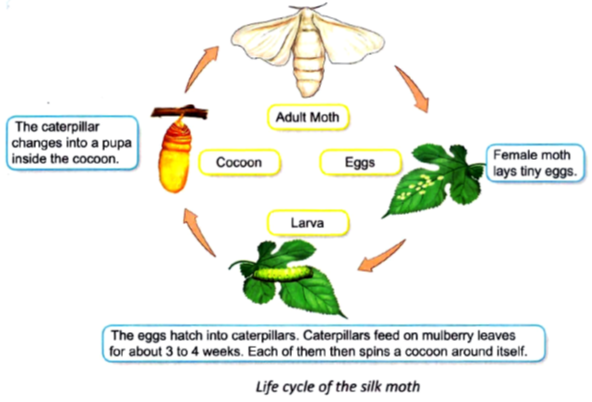

The female species of silk moth lays eggs on leaves. After 20 days, eggs hatch into larvae. these hatched larvae are known as Silkworms or Caterpillars.

(i) The silkworms are fed on mulberry leaves for about 6 weeks. As a result, they grow in size and enter their next life cycle called Pupa. Pupa holds itself by weaving a net around its body by swinging its head in figure of eight (8). While swinging their head, silkworm secretes a wet sticky substance. This substance is made up of protein, which hardens on exposure to air and becomes silk fibre. This way silkworm covers itself completely in the covering known as Cocoon. By the time of completion, cocoon pupa, develops into Adult Moth.

(ii) After complete development of silkworm, the cocoons are gathered and kept under the sun or boiled or exposed to steam, Boiling releases the silk fibres from cocoon. The silk fibres from many cocoons are brought together to form a single silken thread. This process is known as Reeling of silk. Reeling is done in special machines which unwind the fibres of silk from the cocoons.

(iii) Broadly, 3 grades of silk is obtained from a cocoon. The unwound fibres form the finest quality silk called the reeled silk. It is dazzling white in colour. Silk that remains after the reeling process from the damaged or waste cocoon is carded and combed. It constitutes an inferior quality of silk called the spun silk. It is slightly honey-coloured. After carding or combing, the short fibres which are left behind constitute an even inferior quality of silk called the Nail Silk. It has rough texture as compared to reeled and spun silk.

(iv) Throwing is the process by which the obtained silk fibres are twisted into a strand for weaving to prevent silk yarn from splitting into individual fibres. These strands are industry ready to be turned into clothes.

(b) Summary of sericulture

Remember

• Silk is considered the queen of fibres. It is used for making dress materials, saris, scarves, jackets, gloves and carpets.

• Silk fibre is mainly made of two proteins : sericine and fibroin

• Pheromones : These are chemical secreted by an insect to attract the attention of other members of its species.

(c) Varieties of Silk

• The damaged or waste cocoons are used to produce an inferior quality of silk called spun silk.

• Crepe is a kind of silk thread made by twisting individual threads of raw silk, then doubling two or more of these together and twisting them again.

• Tram is the type of silk thread made by twisting two or more silk threads together in only one direction.

• Thrown singles is the type of silk, in which individual threads are twisted in only one direction.

• Organizing is the type of silk thread made by twisting a thread in one direction bringing two or more such threads together and twisting them in the opposite direction.

• mulberry silk is produced by Bombyx mori worms. These worms are fed on the leaves of mulberry trees.

• Eri Silk is produced by Philosomia ricin worms. These worms are fed on leaves of oaster trees leaves.

• Tusser silk and Muga silk are produced by Anheraea Mylitta worms.

Remember

• Semi-synthetic fibres :

These are obtained from naturally occurring fibres by chemical modifications. For example, cellulose on reaction with acetic anhydride in the presence of concentrated sulphuric acid gives cellulose diacetate, which is used for making threads of acetate and other materials like films and glasses.

• Synthetic (artificial) fibres :

Synthetic fibres are manufactured by man in the laboratories. For example: nylon, acrylic and polyester.

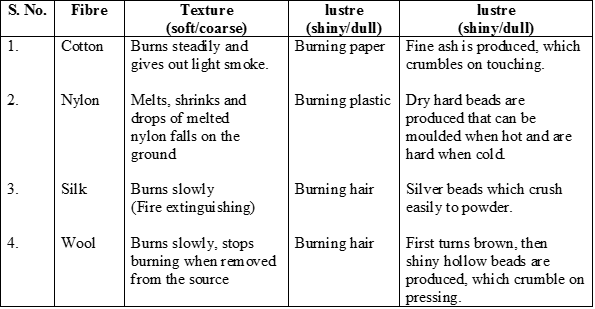

1.4 Burning characteristics of various fibres

Silk

Silk

Silk is one of the most delicate, popular, strong, soft, shiny, and expensive fibres obtained from silkworms. The rearing of silkworms for obtaining silk is called sericulture. The steps in the life cycle of a silkworm are Egg → Silkworm → Pupa → Adult Moth. When a female moth lays eggs, its life cycle starts, and larvae secrete a fine filament made of fibroin protein that forms cocoons.

Param Publication

Param Publication

Grow Career Publication

Grow Career Publication