- Books Name

- Yash Tyagi Coaching Science Book

- Publication

- ACERISE INDIA

- Course

- CBSE Class 9

- Subject

- Science

Separation of Mixtures

1. To obtain colored component (dye) from Ink

Materials Required: Watch glass, Ink (blue/ black), Beaker, Stand, Burner

Procedure

1. Take a beaker and fill it half with water.

2. Take few ml of ink (Blue/ black) in the watch glass and place it on the mouth of the beaker.

3. Start heating the beaker and observe.

4. Heating is continued as long as the evaporation is taking place

5. Heating is stopped when no further change can be noticed on the watch glass

Observation

1. Evaporation taking place from the watch glass can be seen

2. Residue is left on the watch glass

Conclusion drawn

1. It can be concluded that,” Ink is not a pure substance but it is a mixture of dye in water which can easily be separated by evaporation method”.

2. Ink is not a single substance

3. Evaporation taking place from the watch glass containing ink.

Applications of evaporation process are as follows

1. This method can be used to separate the volatile component (solvent) from its non-volatile solute.

2. To obtain common salt from sea water. Sea water is trapped in small shallow pits (called lagoons) and is allowed to stand there for a few days. During this time the heat of the Sun evaporates water in these pits leaving behind the solid salt. This salt is further purified by crystallization method which you will study in the later part of this chapter.

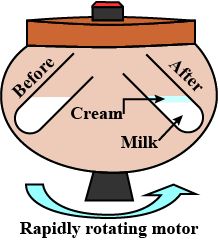

2. To separate cream from milk by using centrifugation method.

Materials Required: Full cream milk, Centrifuging machine/milk churner, Jug test-tubes

Procedure

1. Take un boiled cold milk in two test-tubes and place these test-tubes in a centrifuging machine .

2. Centrifuge it at high speed by using a hand centrifuging machine for two minute and observe.

Note: If you don’t have centrifuging machine in your school then you can do this activity by using a milk churner used in the kitchen.

Observation:

Cream floating on the milk can be seen

Conclusion drawn:

When milk is rotated at high speed, then the suspended lighter particles (fats and protein molecules) bind with each other forming ‘cream’ and ‘skimmed milk’. The cream being lighter, floats over the skimmed milk which can be removed easily.

Applications of centrifugation method are as follows

1. This technique is used in washing machines to squeeze out water from wet clothes and make them dry.

2. This technique is used in diagnostic laboratories for testing cholesterol lipids in blood, ESR (Erythrocyte Sedimentation Rate) and various other types of tests.

3. It is used in dairies for separating cream from milk and butter from curd.

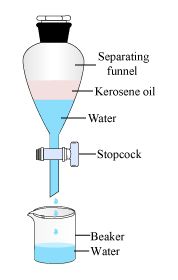

3. To separate kerosene oil from water by using a separating funnel.

Materials Required: Separating funnel, Iron stand, kerosene oil, Beaker, Water.

Procedure

1. A mixture of kerosene oil and water is taken in a separating funnel. The separating funnel is clamped on an iron stand.

2. The mixture is allowed to stand so that it forms two distinct layers.

3. A clean beaker is placed below and the stop cock is opened slowly so that water falls into the beaker.

4. Close the stop- cock of the separating funnel as the oil reaches the stop cock.

Observation:

Kerosene oil being lighter forms the upper layer.

Conclusion drawn:

When a liquid mixture containing two immiscible liquids is taken in a separating funnel, then the liquid layers stand one above the other. The liquid layer with greater density forms the lower layer whereas the lighter liquid (having lower density) forms the upper layer.

Applications of this method are as follows

1. They separate mixture of oil and water.

2. In the extraction of iron from its ore, the lighter slag is removed from the top by this method to leave the molten iron at the bottom in the furnace.

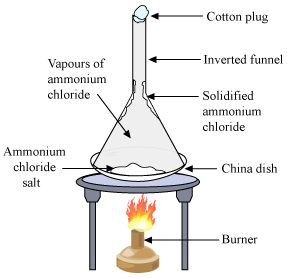

4. To separate a mixture of common salt and ammonium chloride

Materials Required: China dish, Tripod stand, Mixture of common salt and ammonium chloride, Glass funnel, Cotton, Burner.

Procedure

1. Take the mixture of sand and ammonium chloride in a china dish.

2. Cover the china dish with an inverted glass funnel and place it on a tripod stand.

3. Put a loose cotton plug in the opening of the funnel so as to prevent the escape of ammonium chloride vapours.

4. Heat the china dish on a low flame and observe.

Observation

1. White fumes (vapours) of ammonium chloride can be seen coming out of the mixture.

2. These white fumes start depositing as white solid, on coming in contact with the cold, inner walls of the funnel.

3. Sand salt is left behind in the china dish.

Conclusion drawn:

Ammonium chloride, being a volatile substance, changes into white vapours easily which deposit on the cold inner wall of the funnel. This ammonium chloride obtained and is called as Sublimate. Some other examples of solids which sublime are: Iodine, camphor, naphthalene and anthracene.

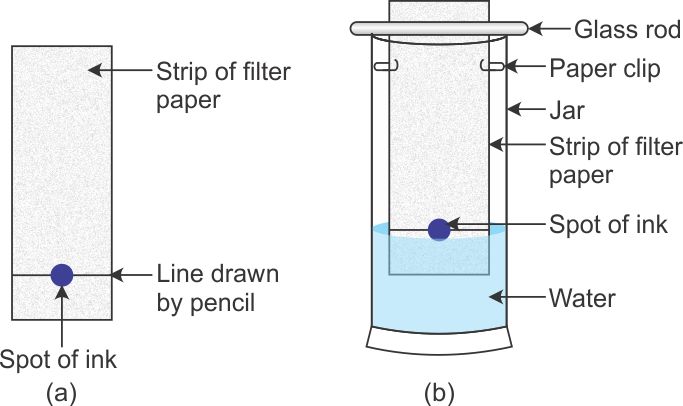

5. To separate the dyes (colored components) present in black ink.

Materials Required: Strip of filter paper, Water soluble ink ( sketch pen or fountain pen), Large size glass jar with lid, Cotton, Thread.

Procedure

1. Take a thin strip of filter paper (25cm x 5cm approx).

2. Draw a line on it using a pencil, approximately 3cm above the lower edge.

3. Put a small drop of water soluble black ink from a sketch pen or fountain pen) at the centre of the line. Let the ink dry.

4. Attach the paper strip on the thread with the help of cello tape.

5. Lower the filter paper strip into a large size gas jar in such a way that the drop of ink on the paper is just above the water level.

6. Adjust the thread and fix it on the sides of gas jar with the help of cello tape.

7. Cover the gas jar with a lid and leave it undisturbed.

8. Watch carefully as the water rises up on the filter paper.

9. Remove the filter paper strip, dry it and observe.

Observation:

Three colored spots can be seen on the filter paper strip.

Conclusion:

The given sample of black ink has three different dyes mixed in it.

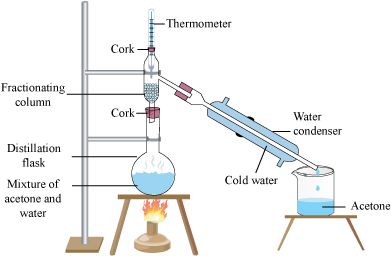

6. To separate a mixture of two miscible liquids (acetone and water).

Materials Required: Distillation flask, Thermometer, Condenser, Beaker, Iron stand, Mixture of acetone and water.

Procedure

1. Take the mixture in a distillation flask. Fit the flask with a thermometer.

2. Arrange the apparatus as shown in the figure.

3. Heat the mixture slowly, keeping a close watch at the thermometer and observe what happens.

Observation

1. The vapours of acetone can be seen rising up in the distillation flask with the increase in temperature.

2. When the temperature rises above 60o, the acetone gets vapourized and forms vapours in the flask.

3. These vapours get condensed in the condenser and can be collected (as pure liquid distillate) from the condenser outlet.

Result

Acetone can be collected in the beaker from the condenser outlet while water is left behind in the distillation flask.

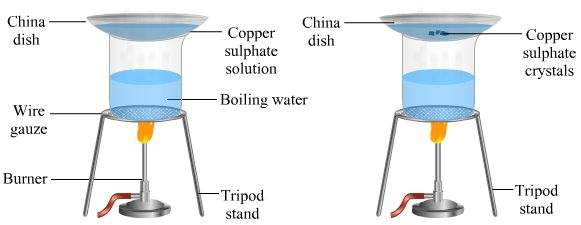

7. To obtain crystals of pure copper sulphate salt from an impure sample by crystallization method.

Materials Required: Impure sample of copper sulphate, Beaker, China dish, Glass rod.

Procedure

1. Take about 5 grams of impure sample of copper sulphate in a china dish.

2. Dissolve it in minimum amount of water.

3. Filter the copper sulphate solution to remove the insoluble impurities.

4. Heat the copper sulphate solution gently on a water bath until it becomes saturated and reaches its crystallization point.

5. Crystallization point can be checked by taking some solution on a glass rod and waving it in the air. When a solid film (small crystals) is formed on the glass rod, then further heating is stopped. This indicates that the solution has been concentrated to crystallization point.

6. Place the china dish on the table after covering it with a watch glass. Leave it undisturbed at room temperature to cool slowly for a day and observe thereafter.

Observation

Crystals of copper sulphate can be seen in the china dish along with the mother liquor (the residual liquid which is left after crystallization).

Conclusions drawn

Hot and concentrated solution of any pure substance forms crystal on cooling gradually.

Result:

Pure crystals of copper sulphate are separated from the mother liquor. These crystals are dried further between the folds of a filter paper or on a porous plate.

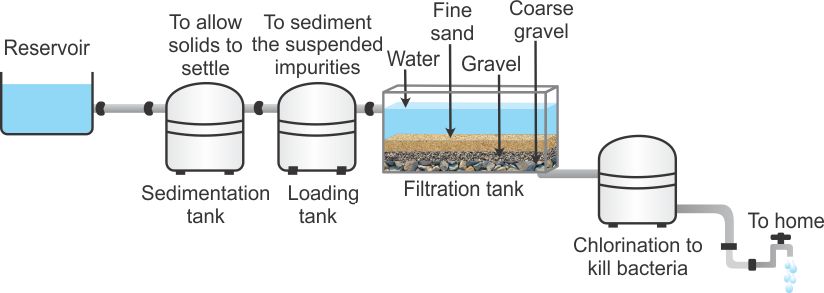

8. Purification of surface water

The purification of surface water can be done through following steps

Sedimentation → loading → filtration → chlorination.

1. Sedimentation: The river water is pumped into a series of sedimentation tanks where it is allowed to stay for a day. Heavy particles of clay and other impurities settle down at the bottom due to the effect of gravity. The supernatant water is then sent to another settling tank.

2. Loading: In next chamber, water is treated with chemicals, i.e. alum and lime to get further settling of impurities.

3. Filtration: The clear water from the second tank is pumped into filtration tank where sand and gravel filter completely remove the suspended impurities.

4. Chlorination: The clear water is chlorinated with a calculated amount of chlorine in the chlorination tank. This process kills harmful bacteria and germs and provides safe drinking water.

Science Made Easy

Science Made Easy

ACERISE INDIA

ACERISE INDIA