- Books Name

- ACME SMART COACHING Chemistry Book

- Publication

- ACME SMART PUBLICATION

- Course

- CBSE Class 12

- Subject

- Chemistry

Corrosion

It is a process of deterioration of a metal as a result of its reaction with air or water (environment) surrounding it.

In case of iron, corrosion is called rusting. Chemically, rust is hydrated form of ferric oxide, Fe2O3 .xH2O Rusting of iron is generally caused by moisture, carbon dioxide and oxygen present in air.

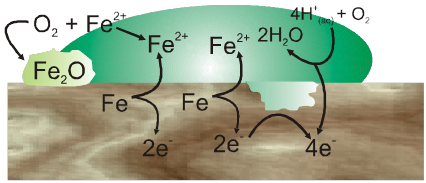

Mechanism of corrosion :

Oxidation :

Fe(s) ![]() Fe2+ (aq) + 2e–

Fe2+ (aq) + 2e–

Reduction :

2O2–(g) + 4H+ (aq) ![]() 2H2O(I)

2H2O(I)

Atomospheric oxidation :

2Fe2+(aq) + 2H2O(l) + 1/2O2 ![]() Fe2O3(s) + 4H+(aq)

Fe2O3(s) + 4H+(aq)

Factors which affect corrosion : The main factors which affect corrosion are

Rate of corrosion µ Rectivity of metal

µ Presence of impurities.

µ Presence of electrolytes.

µ temperature (with in a reason able limit)

Corrosion protection : Corrosion of metals can be prevented in many ways. Some commonly used methods are

(i) By surface coating

(a) By applying, oil, grease, paint or varnish on the surface.

(b) By sacrifical protection; coating/depositing a thin layer of any other metal which does not corrode. For example, iron surface can be protected from corrosion by depositing a thin layer of zinc, nickel or chromium on it.

(c) By Galvanization : Prevention of corrosion of iron by Zn coating.

(ii) cathodic protection : (By connecting metal to a more electropositive metal) In presence of the more electropositive metal, the given metal does not get corroded. For example, iron can be protected from corrosion by connecting it to a block/plate of zinc or magnesium.

(iii) By forming insoluble phosphate or chromate coating : Metal surfaces are treated with phosphoric acid to form an insoluble phosphate. Formation of a thin chromate layer also prevents the corrosion of metals.

(iv) Using anti – rust solutions : Solutions of alkaline phosphates and alkaline chromates are generally used as anti – rust solutions.

ACME SMART PUBLICATION

ACME SMART PUBLICATION