- Books Name

- ACME SMART COACHING Chemistry Book

- Publication

- ACME SMART PUBLICATION

- Course

- CBSE Class 12

- Subject

- Chemistry

Chapter 6

General principles and processes of isolation of elements

Introduction :

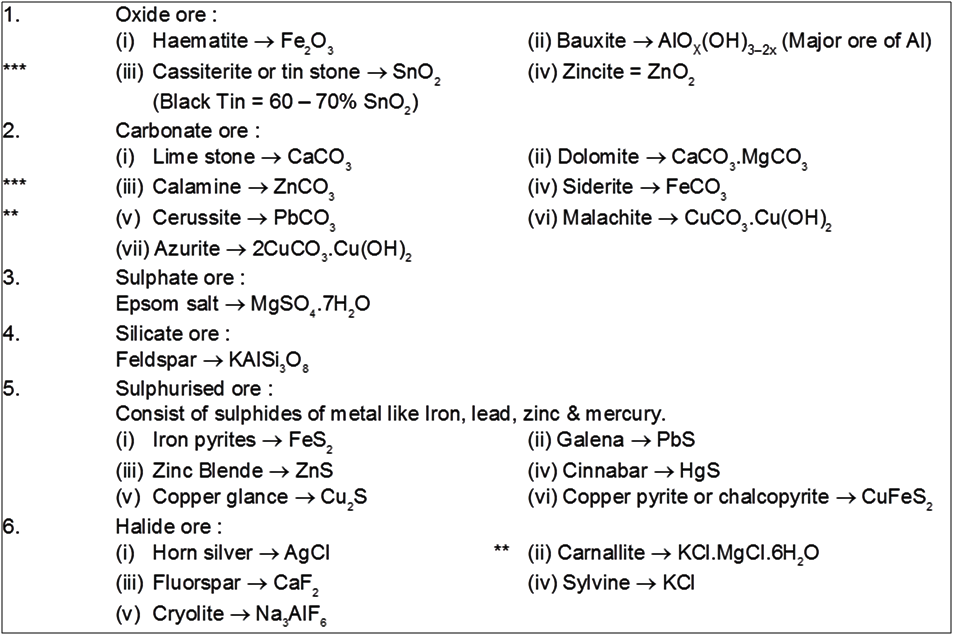

The compound of a metal found in nature is called a mineral. The minerals from which metal can be economically and conveniently extracted are called ores. An ore is usually contaminated with earthy or undesired materials known as gangue. So all minerals are not ores but all ores are minerals. Ores may be classified mainly into following four classes.

(a) Native ores : They contain the metal in free state. Silver, gold, platinum etc, occur as native ores.

(b) Oxidised ores : These ores consist of oxides or oxysalts (e.g. carbonates, phosphates, sulphates and silicates ) of metals.

(c) Sulphurised ores : These ores consist of sulphides of metals like iron, lead, zinc, mercury etc.

(d) Halide ores : These ores consist of halides of metals.

Important ore :

Note : Mg obtained from both sea water & earth crust.

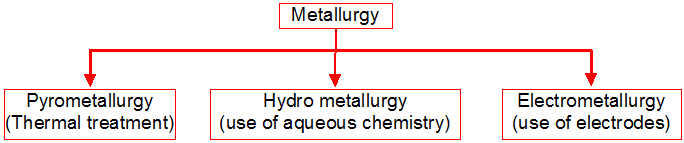

Metallurgy :

The scientific and technological process used for the extraction/isolation of the metal from its ore is called as metallurgy.

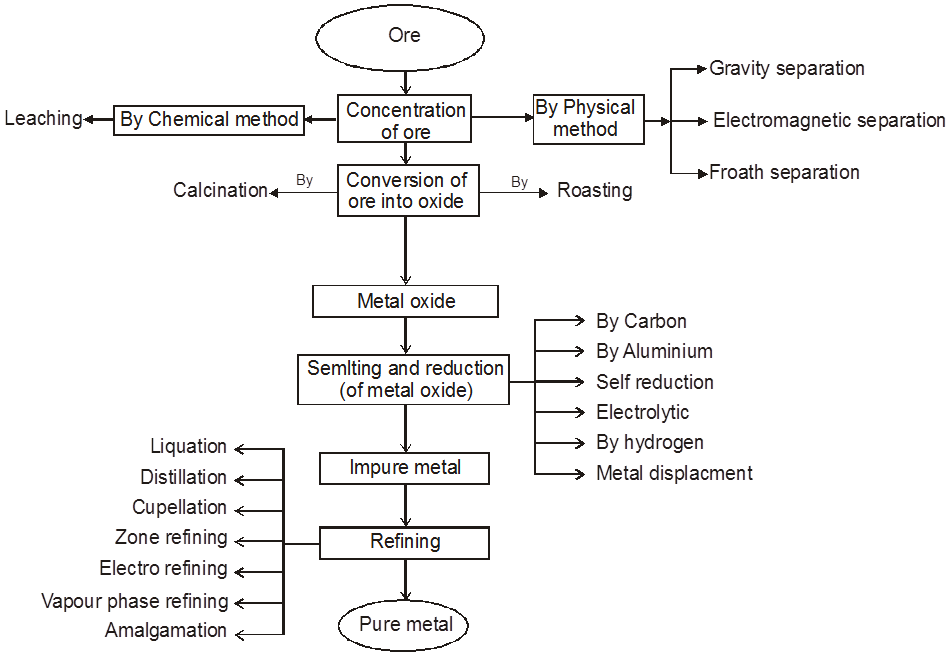

The isolation and extraction of metals from their ores involve the following major steps:

(A) Crushing of the ore.

(B) Dressing or concentration of the ore.

(C) Isolation of the crude metal from its ore

(D) Purification or refining of the metal.

Chart1:

Chart2: Steps involved in metallurgy.

1. Physical Method :

(A) Crushing and Grinding : The ore is first crushed by jaw crushers and ground to a powder (pulverisation of the ore) in equipments like ball mills and stamp mills.

(B) Concentration : The removal of unwanted useless impurities from the ore is called dressing, concentration or benefaction of ore.

It involves several steps and selection of these steps depends upon the difference in physical properties of the compound of metal and that of gangue. Some of the important procedures are described below.

(i) Hydrolytic washing :

Gravity separation or "Levigation". Based on the difference in the densities of the gangue and ore particle.

Generally used for the concentration of oxide & native ore.

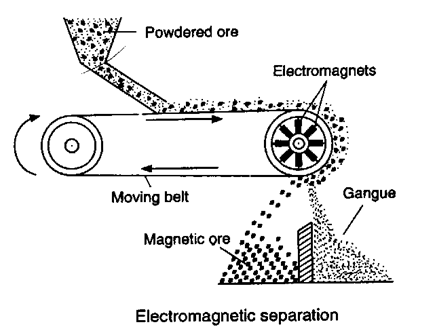

(ii) Electromagnetic sepration :

Based on difference in magnetic properties of mineral and gangue particle.

(a) Chromite ore [FeO.Cr2O3] is seprated from non magnetic silicious impurities.

(b) Cassiterite ore [SnO2] is seprated from magnetic wolframite [FeWO4 + MnWO4]

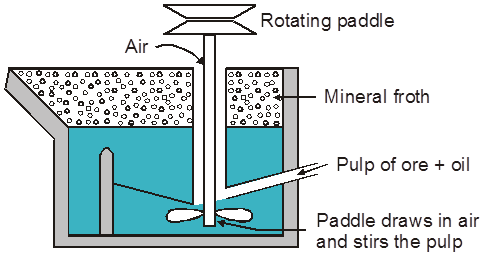

(iii) Froth floatation process :

Generally used for concentration of low grade sulphide ore PbS, ZnS, Cu2S, CuFeS2

Principle :

Based on fact that mineral & gangue particles have different wettability in water and oil (pine oil used)

Mineral particle ® are wetted by oil.

Gangue particle ® Wetted by water.

Reagents Used :

(i) Frothers :

These form stable froth which rises to the top of the flotation cell.

Oil like pine oil, comphor oil are used in small quantities.

Main Function of :

Frother ® Stick to ore & then take it to rise upto the top.

Stabilizer ® To stabilize the froth, froth stabilizer like [cresol & aniline] are added.

(ii) Collector :

K+ or Na+ ethyl xanthates![]() (R = alkyl,M+ = Na+ , K+) are used as collectors. Which collect or attract mineral partical and make them water repellant.

(R = alkyl,M+ = Na+ , K+) are used as collectors. Which collect or attract mineral partical and make them water repellant.

Main Function : Make the ore hydrophobic.

(iii) Activating & Depressing agents :

In PbS + ZnS + FeS2 mixture NaCN + Na2CO3 is used to depress the floation properties of ZnS & FeS2.

ZnS + CN– ¾® [Zn(CN)4]2–

FeS2 + CN– ¾® [Fe(CN)6]4–

CuSO4 is then added which is activating for ZnS as Cu forms more stable complexing with CN– than Zn2+

2. Chemical Method :

(4) Leaching :

Used when ore is soluble in some suitable solvent like ® acid, base & suitable chemical reagent.

Ex. (a) Leaching of alumina from bauxite.

(b) Extraction of Ag & Au from their ores in the complex form by treatment with NaCN & KCN.

(c) Treatment of low grade Cu ores with conc. H2SO4.

(C) Extraction of crude metal from concentrated ore :

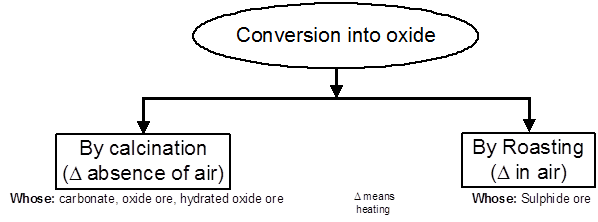

The concentrated ore must be converted into a form which is suitable for reduction. Usually the sulphide ore is converted to oxide before reduction. Oxides are easier to reduce. Thus isolation of metals from concentrated ore involves two major steps as given below.

(i) Conversion to oxide

(ii) Reduction of the oxide to metal.

(i) Conversion to oxide :

Conversion of ore into oxide is carried out in two ways depending upon the nature of ore.

Calcination. It is a process of heating the concentrated ore strongly in a limited supply of air or in the absence of air. The process of calcination brings about the following changes :

(a) The carbonate ore gets decomposed to form the oxide of the metal, e.g.,

FeCO3 (siderite) ![]() FeO + CO2

FeO + CO2

PbCO3 (cerrussite) ![]() PbO + CO2

PbO + CO2

CaCO3 (calcite ore / lime stone) ![]() CaO + CO2

CaO + CO2

ZnCO3 (calamine) ![]() ZnO + CO2

ZnO + CO2

CuCO3.Cu(OH)2 (malachite) ![]() 2CuO + H2O + CO2

2CuO + H2O + CO2

MgCO3.CaCO3 (dolomite) ![]() MgO + CaO + 2CO2

MgO + CaO + 2CO2

(b) Water of crystallisation present in the hydrated oxide ore gets lost as moisture, e.g.,

2Fe2O3.3H2O (limonite) ![]() 2Fe2O3(s) + 3H2O(g)

2Fe2O3(s) + 3H2O(g)

Al2O3. 2H2O (bauxite) ![]() Al2O3 (s) + 2H2O(g)

Al2O3 (s) + 2H2O(g)

c) Organic matter, if present in the ore, gets expelled and the ore becomes porous. Volatile impurities are removed.

Roasting :

Generally used for sulphide ore.

Process : Concentrated ore is strongly heated in excess of air or O2 below its metling point.

(a) Roasting at moderate temperature :

2PbS + 3O2 ![]() 2PbO + 2SO2

2PbO + 2SO2

2ZnS + 2O2 ![]() 2ZnO + 2SO2

2ZnO + 2SO2

If temperature is low (500°C) & concentration of SO2 is high sulphate are produced.

PbS + 2O2 ![]() PbSO4

PbSO4

ZnS + 2O2 ![]() ZnSO4

ZnSO4

(b) Roasting at High temperature :

Self reduction / auto reduction / air reduction :

Sulphide ore of Cu, Pb, Hg & Sb when strongly heated in free supply of air, directly reduced to the metal this known as self reduction.

Cu2S (Copper glance) + O2 ¾® 2Cu + SO2

PbS (Gelena) + O2 ¾® Pb + SO2

HgS (Cinabar) + O2 ¾® Hg + SO2

Important Points

1.It remove impurities of As as As2O3, sulphur as SO2, P as P4O10 & Sb as Sb2O3

4M (M = As, Sb) + 3O2 ¾® 2M2O3↑

S + O2 ¾® SO2↑

P4 + 4O2 ¾® P4O10↑

2. Impurities of CuS & FeS in SnO2 converted to CuSO4 & FeSO4

CuS + 2O2 ![]() CuSO4

CuSO4

FeS + 2O2 ![]() FeSO4

FeSO4

Note : Calcination & Roasting carried out in a reverberatory furnace.

Smelting :

Slag formation : In many extraction processes, an oxide is added deliberately to combine with other impurities and form a stable molten phase immiscible with molten metal called a slag. The process is termed smelting.

The principle of slag formation is essentially the following :

Nonmetal oxide (acidic oxide) + Metal oxide (basic oxide) ¾® Fusible (easily melted) slag

Removal of unwanted basic and acidic oxides: For example, FeO is the impurity in extraction of Cu from copper pyrite.

2CuFeS2 + 4O2 ¾® Cu2S + 2FeO + 3SO2

Cu2S + FeO + SiO2 ¾® FeSiO3 (Fusible slag) + Cu2S (matte)

![]() (upper layer) (lower layer)

(upper layer) (lower layer)

Matte also contains a very small amount of iron(II) sulphide.

To remove unwanted acidic impurities like sand and P4O10, smelting is done in the presence of limestone.

CaCO3 ¾® CaO + CO2

CaO + SiO2 ¾® CaSiO3 (fusible slag)

6CaO + P4O10 ¾® 2Ca3(PO4)2 (fusible slag - Thomas slag)

Properties of a slag :

(i) Slag is a fusible mass.

(ii) It has low melting point.

(iii) It is lighter than and immiscible with the molten metal. It is due to these impurities that the slag floats as a separate layer on the molten metal and can thus be easily separated from the metal. The layer of the slag on the molten metal prevents the metal from being oxidised.

Type of flux : Fluxes are of two types viz., acidic flux and basic flux.

(a) Acidic flux : It is an acidic oxide (oxide of a non-metal) like SiO2, P2O5, B2O3 (from borax). It is used to remove the basic impurity like CaO, FeO, MgO etc. The acidic flux combines with the basic impurity and forms a slag.

(b) Basic flux : It is a basic oxide (i.e., oxide of a metal) like CaO (obtained from lime stone, CaCO3), MgO (from magnesite, MgCO3), haematite (Fe2O3) etc. It is used to remove the acidic impurity like SiO2, P2O5 etc. The basic flux combines with the acidic impurity and forms a slag.

Thus, slag can be defined as a fusible mass, which is obtained when a flux reacts with an infusible acidic or basic impurity present in the oxide ore.

Reduction of a Metal Oxide

(1) Reduction with Carbon :

PbO + C ¾® Pb + CO

2Fe2O3 + 3C ¾® 4Fe + 3CO2

*** ZnO + C ![]() Zn + CO (Extraction of Zn)

Zn + CO (Extraction of Zn)

*** SnO2 + 2C ![]() Sn + 2CO

Sn + 2CO

(2) Reduction with CO :

Fe2O3 + 3CO ¾® 2Fe + 3CO2

Fe3O4 + 4CO ¾® 3Fe + 4CO2

Reduction with C & CO is carried out in blast furnace.

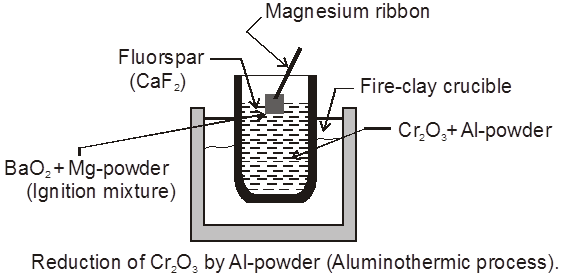

(3) Redution with Al :

GoldSchmidt or Aluminothermic process :

Metallic oxide of Cr & Mn reduced by Al & this reaction is known as thermite reaction.

Mg + BaO2 ¾® BaO + MgO + Heat

(i) Cr2O3 + Al ¾® 2Cr(l) + Al2O3

*** (ii) 3Mn3O4 + 8Al ¾® 4Al2O3 + 9Mn

(iii) 2Al + Fe2O3 ¾®Al2O3 + 2Fe

(iv) B2O3 + 2Al ¾® 2B + Al2O3

(4) Redution by Mg & Na :

(i) TiCl4 + 2Mg ![]() Ti + 2MgCl2

Ti + 2MgCl2

(ii) TiCl4 + 4Na ![]() Ti + 4NaCl

Ti + 4NaCl

(5) Self reduction or auto reduction or air reduction :

Sulphide ore of some of the metal like Hg, Cu, Pb & Sb, when heated in air some part of these ore change into oxide or sulphate, thenthat part react with remaing part of sulphide ore to give its metal & sulphur dioxide.

This process is known as self reduction.

Ex. (i)(a) 2PbS + 3O2 ¾®2PbO + 2SO2

2PbO + PbS ¾®3Pb + SO2

(b) PbS + 2O2 ¾®PbSO4

PbSO4 + PbS ¾®2Pb + 2SO2

(ii) 2HgS + 3O2 ¾®2HgO + 2SO2

2HgO + HgS ¾®3Hg + SO2

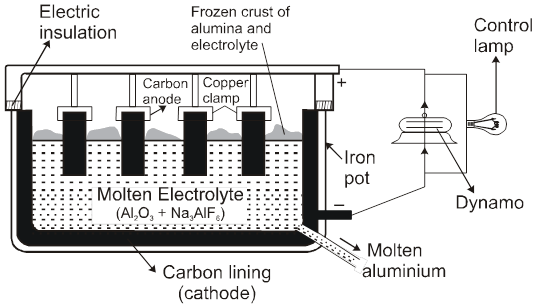

(6) Electrolytic Reduction :

Electrolytic reduction is an expensive method than chemical method, that's why generally we do not use this method.

But when very high pure metal is required then we use this method.

This method is also used for highly reactive metal.

(i) Electrolyric reduction in aqueous solution :

This method is used when product does not react with water.

Electrolytic reduction of Cu & Zn from their sulphates.

(ii) In other solvents : Flourine react with water so it is produced by electrolysis of KHF2 dissolved in anhydrous HF.

(iii) In fused metal : When produced metal react with water, then metal is extracted from fused melt of their ionic salt.

Eg. (i) Al is extracted from electrolysis of fused mixture of Al2O3 and cryolite (Na3AlF6).

(ii) Extraction of Na by electrolysis of fused NaCl.

Note : In this electrolysis CaCl2 is added as impurity to lower the melting point from 800°C to 500°C.

(i) Hydro Metallurgy :

When metal can be extracted using solution without any heating or without any electrolysis then operation is known as hydrometallurgy.

Basic Step

(i) Dissolution of the valuable metal in aqueous solution.

(ii) Purification of leach solution.

(iii) Recovery of metal from purified solution.

Ex. Extraction of Ag & Au :

Metallic Ag dissolved in NaCN from ore of Ag & then precipitated with the help of Zn.

AgS(s) + 4CN¯ ¾® ![]() + S2–

+ S2–

2[Ag(CN)2]¯(aq) + Zn(s) ¾® [Zn(CN)4]2–(aq) + 2Ag(s)

(ii) Pyrometallurgy :

If furnace are used and ore are heated to extract metal then it is called pyrometallurgy.

Electrochemical principles of metallurgy :

Electrolytic reduction can be regarded as a technique for driving a reduction by coupling it through electrodes and external circuit to a reactive or a physical process with a more negative DG. The free energy available from the external source can be assessed from the potential it produces across the electrodes using the thermodynamic relation :

DG = –nFE ..........(i)

where n is the number of electrons transferred, F is Faraday’s constant (F = 96.5 kJ/mol) and Eº is electrode potential of the redox coupled formed in the system.

Hence, the total Gibb’s energy of the coupled internal and external process is

DG + DG (external) = DG – nFEext

If the potential difference of the external source exceeds

Eext = –![]()

the reduction is thermodynamically feasible; thus, the overall process occurs with a decrease in free energy.

More reactive metals have large negative values of the electrode potential. So their reduction is difficult. If the difference of two E0 values corresponds to a positive E0 and consequently negative D G0 in equation (i), then the less reactive metal will come out of the solution and the more reactive metal will go to the solution, e.g.,

Cu2+ (aq) + Fe(s) —® Cu(s) + Fe2+(aq)

In simple electrolysis, the Mn+ ions are discharged at negative electrodes (cathodes )and deposited there. Precautions are taken considering the reactivity of the metal produced and suitable materials are used as electrodes. Sometimes a flux is added for making the molten mass more conducting.

Hydrometallurgy : The processing of ores and minerals as well as metals and their compounds at relatively low, often ambient temperatures employing aqueous solution is known as hydrometallurgy. Occasionally, organic reagents are also used. This method of extraction is generally used for low grade ores. Copper is extracted by hydrometallurgy from low grade ore it is leached out using acid and bacteria. The solution containing Cu2+ is treated with scrap iron or H2.

CuSO4 + Fe —® Cu(s) + FeSO4

A hydrometallurgical process for the extraction of metals from ores, concentrates, or secondary materials essentially contains three basic steps—dissolution of the valuable metal in the aqueous solution (leaching) purification of leach solution and subsequent recovery of metal from the purified solutions either by electrolysis or by adding some electropositive metal to it.

Some of the metals obtained by hydrometallurgy are as follows :

(A) Extraction of Ag and Au : Metals like Au and Ag can be precipitated for their salt solution by electropositive metals for example, Zn.

Metallic Ag is dissolved from its ore in dilute NaCN solution, and the solute so obtained is treated with scrap Zn when Ag is precipitated. Air is blown into the solution oxidize Na2S. Leaching the metals like silver, gold with CN– is an oxidation reaction (Ag ® Ag+ or Au ® Au+)

Ag2S (s) + 4CN– (aq) —® 2 [Ag(CN)2]– (aq) + S2– (aq)

2[Ag(CN)2]– (aq) + Zn (s) —® [Zn (CN)4]2– (aq) + 2Ag (s)

4Au (s) + 8 CN– (aq) + O2 (g) + 2H2O (l)—® 4 [Au(CN)2]– (aq) + 4OH– (aq)

2[Au(CN)2]– (aq) + Zn (s) —® [Zn(CN)4]2– (aq) + 2 Au (s)

Here Zn acts as reducing agent.

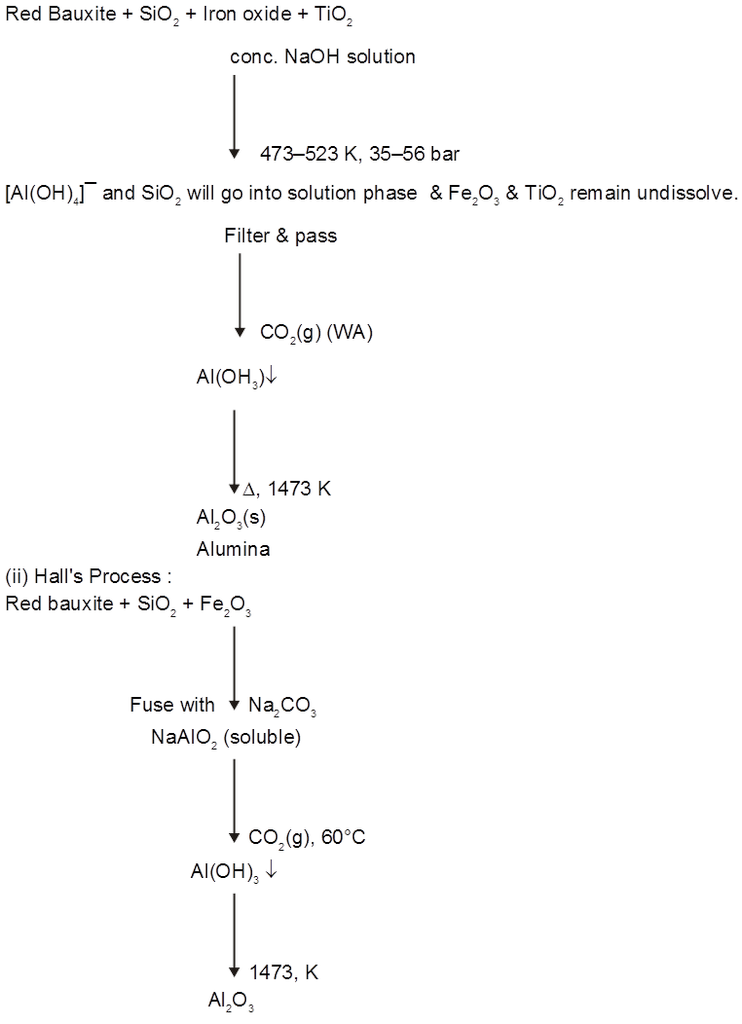

(B) Extraction of Aluminium : It involves the following processes

(a) Purification of bauxite :

(1) Leaching of Alumina from bauxite :

If Fe2O3 is main impurity (red bauxite) ® Bayer's/Hall's

If SiO2 is main impurity (white bauxite) ® Serpeck's process.

(i) Bayer's process :

(iii) Serpeck's process :

Used for white bauxite containg silica as impurities.

Al2O3 + N2 + ![]() Coke AlN + CO ↑

Coke AlN + CO ↑

![]() Al(OH)3 + NH3 ↑

Al(OH)3 + NH3 ↑

![]() Al2O3 (pure)

Al2O3 (pure)

(2) Electrolytic reduction [Hall-Heroult process] :

Electrolysis of fused Al2O3 is difficult as its MP is very high (2323 K) & It is bed conductor of electricity in fused state.

So Al2O3 is mixed with Na3AlF6 or CaF2. Which lowers the MP (1173 K) & make alumina conducting.

Cathode Þ Al3+ (Melt) + 3e– ® Al(l)

Anode Þ C(s) + O2– (Melt) ® CO(g) + 2e–

C(s) + 2O2– (Melt) ® CO2(g) + 4e–

Overall reaction Þ2Al2O3 + 3C ® 4Al + 3CO2

Note : During electrolytic reduction of aluminum, the carbon anodes are replaced from time to time because oxygen liberated at the carbon anodes react with anode to form CO & CO2.

Electrolytic refining of Al :

Hoop's process : For electrolytic refining of Al, Hoop's process is used.

Anode Þ Impure Al

Cathode Þ Pure Al

Electrolyte Þ Fused salt of Aluminium Fluoride

Note :The fused material remain in three different layer & remain separated because all the layer have different density.

Anode Þ Al(melt) ¾® Al3+ + 3e–

Cathode Þ Al3+ + 3e– ¾®Al

From anode (bottom layer), Al passes into solution as Al3+ ions and then from solution (middle layer) these Al3+ ion pass to cathode (top layer) and get reduced to pure metal.

Extraction of Na : The fused mixture of NaCl and CaCl2 is taken in Down’s cell which consists of circular iron cathode and carbon anode. On passing the electric current the following reactions take place :

Ionisation of NaCl : NaCl ![]() Na+ + Cl–

Na+ + Cl–

Collection of Na at cathode : Na+ + e– ® Na(Reduction).

Collection of Cl2 at anode : Cl– + e– ®Cl (Oxidation), Cl + Cl ® Cl2 .

Na can also be obtained by electrolysing molten NaOH in Castner’s cell.

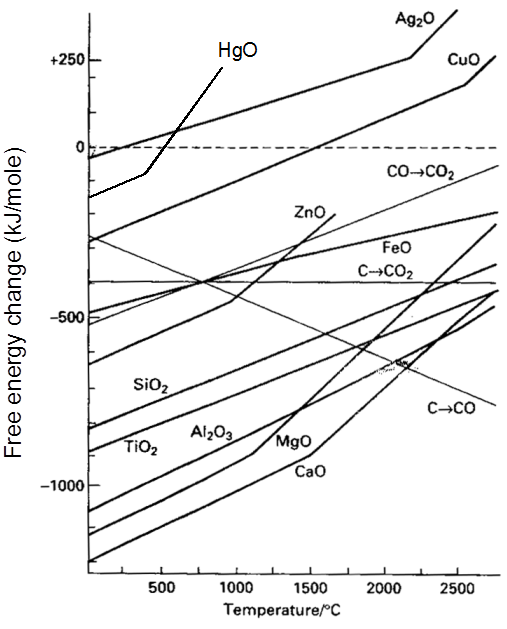

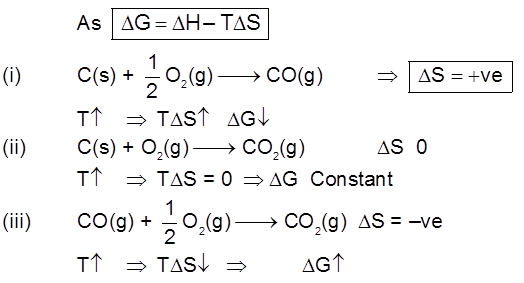

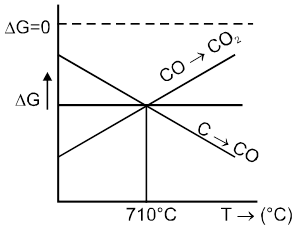

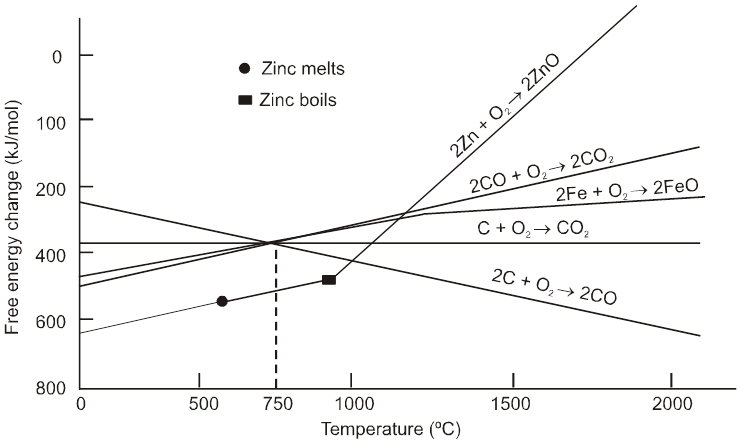

Thermodynamics of extraction : Ellingham Diagram of a Metal

Ellingham Diagram

Thermodynamic of extraction :

For a Proces to be spontaneous D G must be negative.

Ellingham Diagram of Metal

XM(s) + ![]() O2(g) ¾® MXOY(s)

O2(g) ¾® MXOY(s)

number of gaseous moles decreae with progress of reaction.

As DS = –ve If T Þ DG

Important Points

(1) Below 710°C, CO is better reducing agent than C.

(2) All the graphs are upgrowing and on increasing temperature, DG of formation of metal oxide become less negative, while on increasing temperature, DG of C ¾® CO reaction become more negative SO, C can reduce any metal from their metal oxide.

(3) Temperature above which DG of formation of metal oxide become positive, metal oxide become unstable & it decomposes into metal & oxygen.

(4) Theoritically, all metal oxide can be decomposed to give metal & oxygen, if suficiently high temperature is applied.

(5) When plot of one metal oxide is below the others then former metal is capable of reducing the later metal oxide into their metal.

Some important result

(1) All the three oxidation graph of carbon system are above the oxidation graph of ZnO upto temperature 1000°C. At this temperature C is thermodynamically capable of reducing ZnO to Zn. So C is better reducing agent for ZnO to Zn than CO.

(2) Below 1500°C temperature, the graph of MgO lies below the graph of Al2O3, so below this temperature Al cannot reduce MgO, but above this temperature graph of Al2O3 shifts below the graph of MgO so above 1500°C, Al can reduce MgO.

ACME SMART PUBLICATION

ACME SMART PUBLICATION